Storage

Industry floor with levellingConcrete surface showed coarse roughness of the base. The base was ground by diamond. The cracks were removed by plastic concrete. Levelling was used to level the surfaces. The surface was reground. The walkway layer is produced from Epoxy resin with artificial chips pouring in.

Social service house

Industry floorThe project was financed by European funds. Terazzo, pavement and concrete were used as base. Correct selection of penetration kind was decided for the success of the implementation because no levelling was considered for this project. Final walkway Epoxy resin is covered by artificial chips pouring in.

ELNEC

Gas-proof layerThe object is located above the original swimming pool. The investor requested gas-proof paint in the stairway spaces. The pavement was ground, penetrated and grouted by thick layer of Epoxy resin.

AUPARK

Sealing the details and passages of air conditioningOn the object walls, insulating system was produced. We proposed detail of sealing based on self-sticking strip. The strip was heated and imprinted by a roller.

AUPARK

Implementation of engine room insulation / 10th over-ground floorDetail of wall connection with the floor was performed by insertion of strips into the fresh mixture. The base was insulated by continual layer based on the two-component bitumen emphasizing the local passages. The finished hydro-insulation was covered by a geo-textile.

CASSOVAR

Sealing dilatationThe injection was performed according to procedure proposed and projected by us. Horizontal and vertical dilatations with the dimensions of 40 x 250 mm were sealed. When injecting, thixotropic Acrylate resin was used.

AUPARK

Implementation of kitchen/food-court floors insulations 3rd over-ground floorDetail of connection of walls with the floor was performed by insertion of strips into the fresh mixture. The base was insulated by continual layer based on the two-component bitumen emphasizing the local passages. The finished hydro-insulation was covered by a geo-textile.

Private apartment

Injection of enclosure wall, reconstruction of walls and floorsOriginal plaster was cut down. The enclosure wall masonry was injected through by gel based on Acrylate resin. From internal wall, a tray was created from insulating braces. Levelling material was poured to the floor. The walls were levelled by reconstruction plaster.

TATRAMAT

Antistatic floor with higher mechanical loadOriginal pavement was ground by diamond. On the special thixotropic penetration, flattening layer of levelling was applied. Copper raster was applied to the base and it was grounded. Afterwards the surface was rolled by conductive layer. Cavettos were produced along the circumference. The final layer is created by ESD Epoxy resin.

Pile wall

Preventing from material washingDuring the cement injection, excessive material washing was occurred. From this reason, the hoses were injected through by high-expansion foam with rapid reaction start.

Primary school

Preventing from ingress through the floor.The floor showed ingress through unsealed connections and chute. Original pavement was removed. Four insulation layers were applied on the base. The circumference is bordered by cavettos. The final layer is created by Polyurethane coating.

Primary school

Reconstruction of fitness centre wallsOriginal plaster was removed. The bricks were levelled by piecing material. The base was insulated by braces in two layers. Reconstruction plaster was applied to sprayed walls.

ZŤS VVÚ

Epoxy resin coatingOriginal linoleum was removed. The floor was penetrated with Epoxy resin and poured with sand. On this layer, the high-strength levelling material was poured off. After hardening, the resin layer based on the Epoxy was applied.

APOLLO

Implementation of floor insulation in server roomSuspended floor was closed by OSB boards. The base was penetrated and insulated by continual layer based on two-component bitumen emphasizing the local passages. Finished hydro-insulation was covered by geo-textile.

Geča Cottage

Preventing from ingress in cellar spacesIn the object, water from 200 up to 700 mm from the floor level culminated. In the first stage, the water infiltration because of object non-tightness was avoided. In the second stage, surface reconstruction of rooms was performed.

RIVER GARDENS

Insulation of sills and flowerpotsComplexity of detail with plenty of passages required special approach and top-quality liquid insulations. The object was performed in several stages. On sills, securing insulation based on bitumen and main hydro-insulation based on hybrid elastomer were accomplished.

Villa

Reconstruction of walls and floors of the objectOriginal plaster was cut down. The enclosure wall masonry was injected through by gel based on Acrylate resin. From internal wall, a tray was created from insulating braces. Levelling material was poured to the floor to prevent from capillary action of water. The walls were levelled by reconstruction plaster.

Fitness centre

Solid floor to be maintained easilyThe floor was penetrated and poured in by sand. On this layer, the high-strength levelling material was poured off. After hardening, the layer of UV-stable resin based on the Epoxy was applied. The footstall was painted through its overall circumference.

Power plant turbines

Preventing from ingressJoints between the bed of turbine suspensions were injected through by low-viscous Polyurethane resin.

House

House stabilizationGeological research determined the depth of foundation. The Works were performed according to static expertise. The foundations were discovered and additionally reinforced by compacted concrete. The walls were supported by „I“ profiles, which were located on new stems.

CHEMOSVIT

Reconstruction of cooling tower columnsThe columns were blasted by water sprays. The reinforcement was painted by corrosion protection. Thick re-profiling mortar was applied to the base. Fine re-profiling mortar was closed by three layers of special Epoxy paint

Basement spaces of a company

Reconstruction of walls and floors of the objectThe basement is located in historical centre of the town. The reconstruction was performed without necessity of any injecting technology. Original masonry was levelled. Insulation braces in two layers were applied to the base. Levelling materials was poured to the floor to prevent from capillary action of water. Reconstruction plaster was applied to the walls.

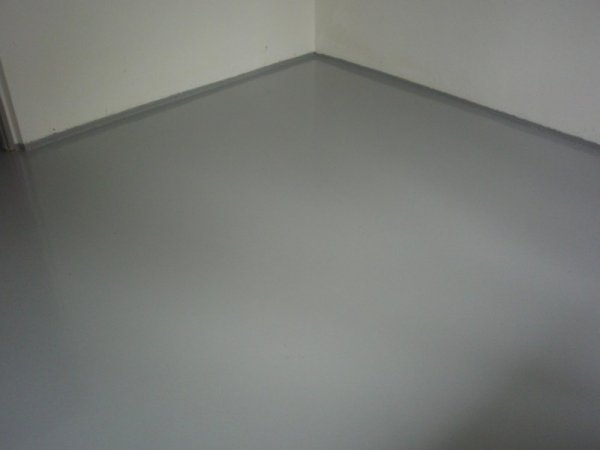

Apartment house

Implementation of Industry floors with levellingOriginal pavement was ground by diamond. On the special thixotropic penetration, flattening layer of levelling was applied. The final Epoxy resin was poured in by white chips.

House

Reconstruction of wet basement spacesOriginal plaster was cut down up to the concrete base. The walls and floors were insulated by fine plaster based on cement. Levelling material was poured to the floor to prevent from capillary action of water. The walls were levelled by reconstruction plaster.

Store rooms

Reconstruction of object wallsAfter cutting down the plaster, the injection of cracks was performed. A slot was milled into the joint between the floor and the wall. The slot was filled by sealing material based on cement. Insulation braces in two layers were applied to the walls.

New building

Preventing from ingress of joint between the board and the object wallObject with basement showed ingress in the area of connection of enclosure wall masonry with the floor. Low-viscous Polyurethane was injected into the joint. Beside joint filling, material penetration into the masonry was performed.

Villas Kalvária

Preventing from ingress into basement spacesCreek regulation caused increase of ground water level in the given locality. The basement was flooded in the height of 200 up to 500 mm from the floor level. In both cases, injection because of static linkage of bricks and following preventing from ingress was performed. After injecting, insulation braces in three layers were performed. The floor was levelled and the walls were flattened by reconstruction plaster.

Primary school

Preventing from ingress, reconstruction of walls and floors of boiler roomOriginal plaster was cut down. The work joints were injected through by Polyurethane resin. From internal wall, a tray was created from insulating braces. Levelling material was poured to the floor to prevent from capillary action of water. The walls were levelled by reconstruction plaster.